Place the borad, mill, saw – within no time the moulded part is finished

Sometimes it can be that simple. With the SUPERCUT milling and sawing tables from flextos, drywall construction professionals save time, money and, above all, manpower in their daily work.

Prefabricated moulded parts made of plasterboard have become indispensable in modern drywall construction. In the past, these were cut by hand on the construction site, but this has been much easier in recent years.

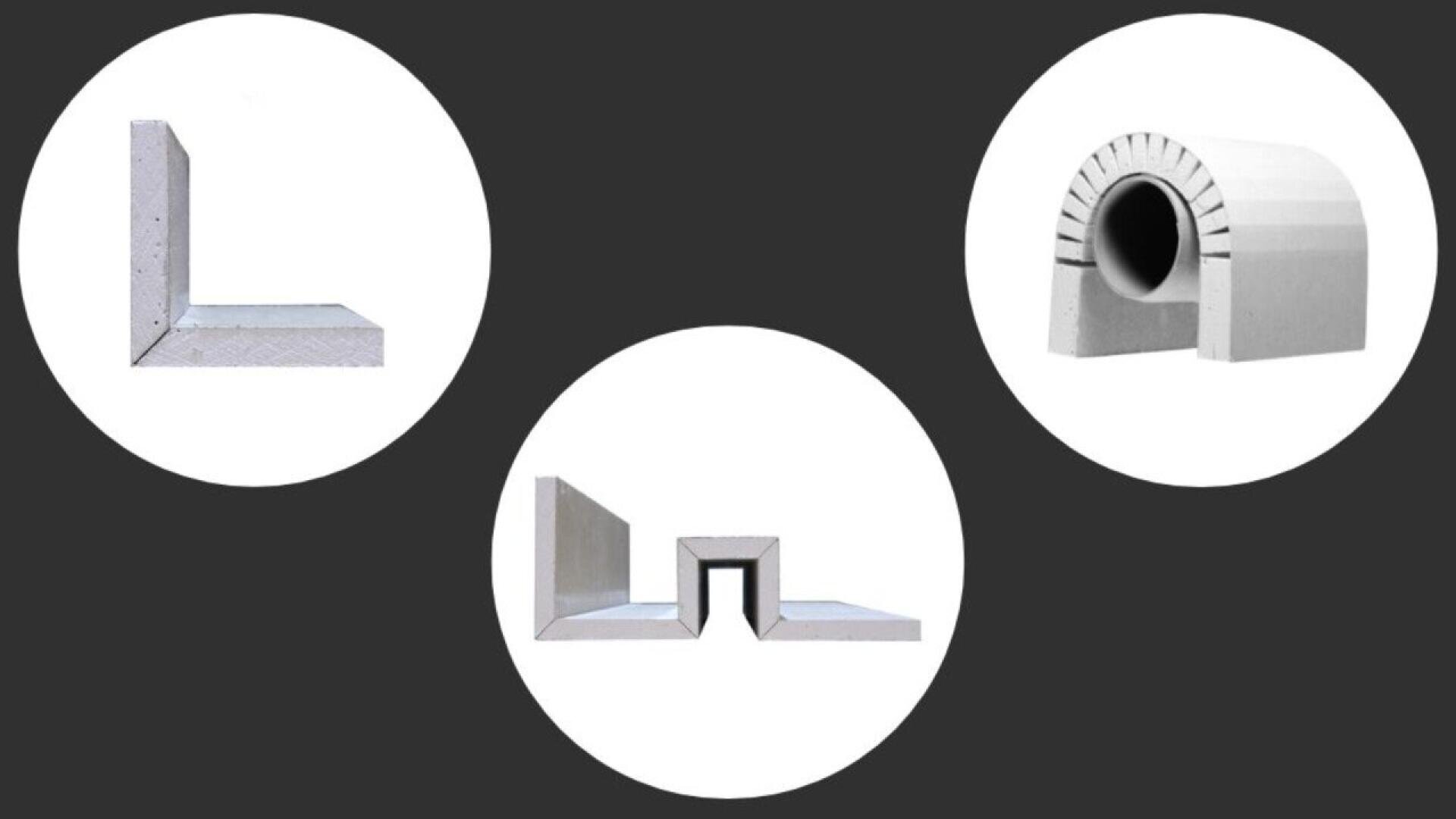

Moulded parts of all kinds + in any size

L-angles, light coves, omega profiles, paper edges, pipe profiles, U-angles, shower niches and much more - with the SUPERCUT routing and sawing tables, all types of moulded parts can be produced in advance in just a few simple steps. Once set up, even the largest quantities can be produced in a very short time.

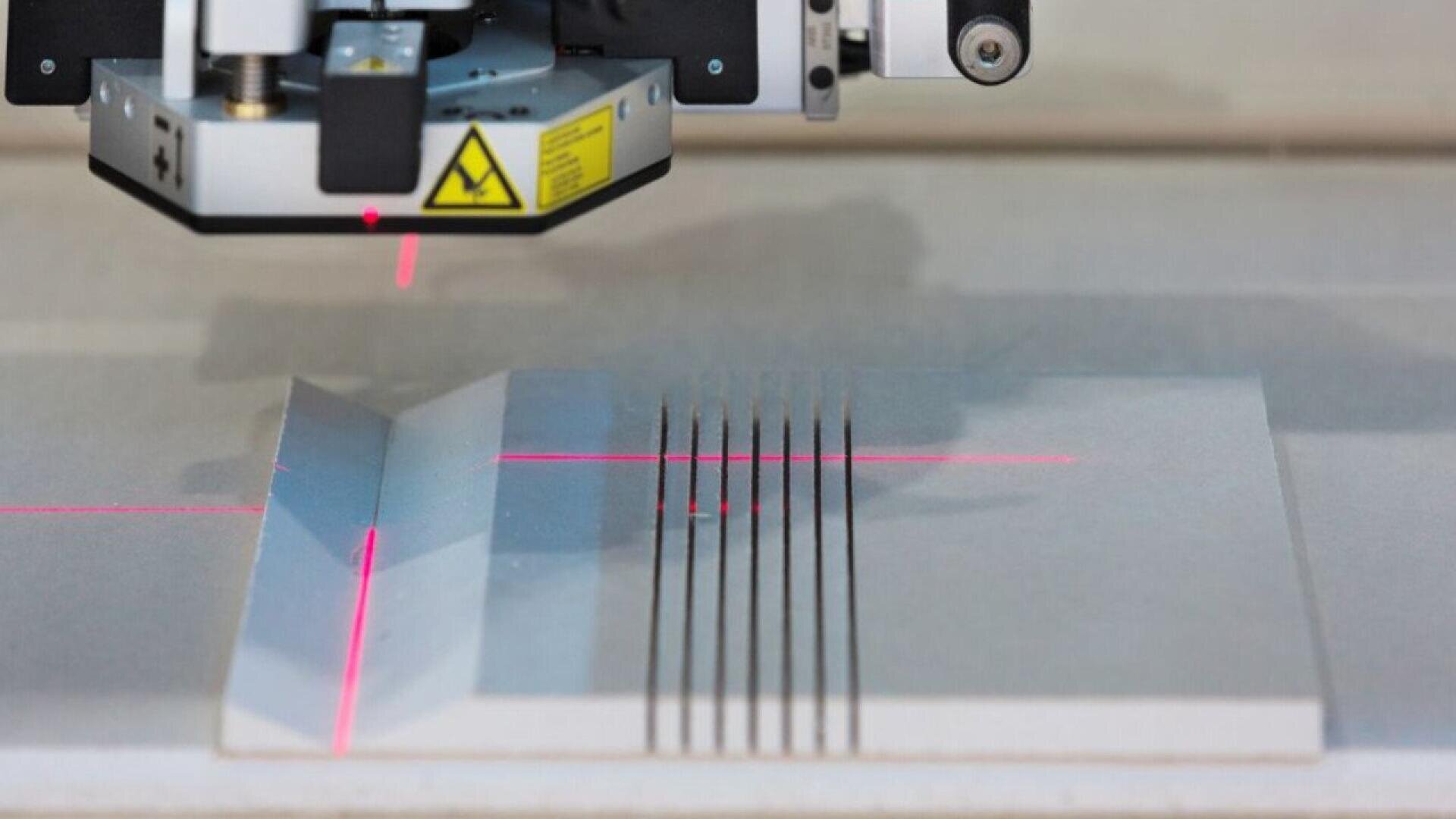

Pre-assembly for easy installation

The operator selects the V-milling cutter required for the moulded part, places the plate - and off you go. The gantries of the SUPERCUT tables are double-equipped: the routing unit is on the right, the saw on the left. This means that the milled plasterboard simply remains on the worktable and is cut directly with the same hand movements as when milling. Round arches are created with the 4- or 7-cut saws.

The milling and sawing process is repeated until all the required elements are available. The moulded parts are then glued together and are later used on the construction site once all assemblies have been completed - prefabricated for quick installation without reworking.

Added value remains with the drywall builder

The advantages of the milling and sawing tables are obvious: first and foremost, you are independent of suppliers with long delivery times and keep the added value completely in-house. In addition, the automated working method saves valuable time and energy, which can be a decisive advantage over competitors, especially in times of labour shortages.

Milling and sawing tables for every application

With the SUPERCUT series, flextos has the right machine in its portfolio for every size of company and all areas of application.

The bestseller is the SUPERCUT XPS: the stationary routing and sawing table is available in two lengths - 4.0 and 4.8 metres for processing multiple panels. If you need to reposition your table frequently during production or transport it to larger construction sites, the mobile SUPERCUT XPK folding table is the right choice. And if you want to take your own moulded part production to the next level and automate it almost completely, opt for the SUPERCUT CNC. Last but not least: the mobile SUPERCUT XPM for use directly on the plasterboard pallet. Smaller milling and sawing jobs can be completed quickly and easily on site with this entry-level model.

Further information at: www.flextos.com.