Advantage: Moulded part

Self-produced moulded parts save time, labour, waste and therefore money - real advantages over competitors. Simply produce the desired moulded part, transport it to the construction site, install it on site - and you're done.

Opinions on prefabricated moulded parts made from plasterboard differ greatly in some cases. Some swear by the complete customisation of the plasterboard panels on the construction site in order to be able to react at short notice. Others prefer to plan in advance and then install the self-made mouldings on site in no time at all. The most efficient way is certainly a combination of both.

Plan ahead + manufacture standard moulded parts yourself in advance

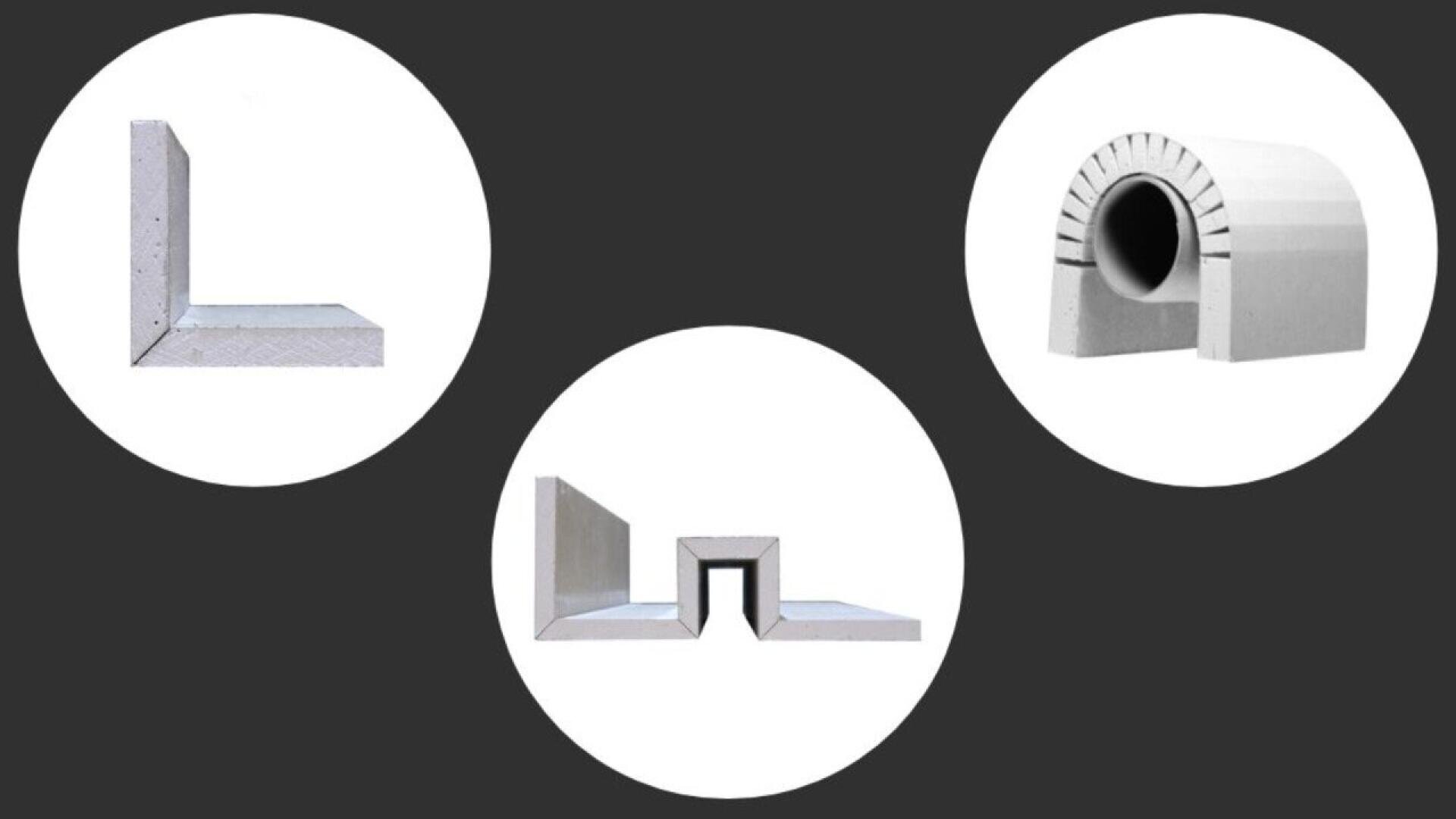

L-angles, light coves, omega profiles, paper edges, pipe profiles, U-angles, shower niches and many other standard moulded parts can be easily measured, planned and manufactured in advance. Precise and accurate, without a lot of waste, without time pressure, manufactured exactly to the point. On the construction site, these moulded parts are then simply installed in the desired position.

Customised products adapted on site at the construction site

Of course, there are always special requests that were not planned when the order was placed. These then have to be customised on site. Although this is more time-consuming, it also demonstrates flexibility and adaptability.

By planning ahead and reacting quickly and effectively to special requests, you demonstrate your professionalism and customer-orientation.

Utilising material + personnel effectively and cost-efficiently

Ideally, both working methods are flanked by the right tools / machines and many years of experience. With the SUPERCUT milling and sawing machines from flextos, drywall materials can be processed both in your own workshop and on site. With this company equipment, a milling and sawing table for moulded parts (workshop/production hall) is supplemented by a mobile machine with which milling, cutting and moulding can be carried out directly on site (construction site).

This makes it possible to perfectly organise staff, material and time. Idle times, waste and faulty parts are now a thing of the past - the customer always receives the same high quality that they expect.

Maximise added value in your own company

This makes you independent of suppliers with long delivery times. With the exception of the plasterboard, you don't have to buy anything in and keep the added value completely in-house. In addition, the automated working method saves valuable time and energy, which can be a decisive advantage over competitors, especially in times of labour shortages.

The right machine for every requirement

For almost 15 years, flextos GmbH from Raubling near Rosenheim has made it its mission to make the work of dry construction companies easier wherever possible. A suitable routing and sawing table or mobile machine is now available for every size of company and all areas of application.

The 15-strong flextos team will be happy to show interested parties how to use the machines effectively and profitably and which model is best suited to their requirements. A smaller table in combination with a mobile machine is often sufficient, in contrast to an automated CNC machine. In addition, flextos offers customer-optimised leasing offers, immediate availability of all machines and parts (same-day dispatch), personal service contacts, milling and sawing units for hire if required and numerous other services.

Further information and callback service at:

www.flextos.com/en or call: 08031 2338860.